Exploring the various uses of switch backlighting in interior design

Wiki Article

The Production Process Behind High-Quality Switch Backlighting Solutions

The manufacturing procedure behind high-quality button backlighting remedies entails a number of critical points. It begins with a collective design stage that combines design and layout insights. Advanced techniques are utilized for prototyping, adhered to by rigorous screening and refinement. As production scales up, a concentrate on top quality products and automated assembly comes to be essential. Quality assurance actions are incorporated throughout, guaranteeing efficiency and resilience. Nonetheless, the complexities of each phase reveal deeper insights right into what absolutely drives excellence in this field.Recognizing the Style Factors To Consider for Switch Backlighting

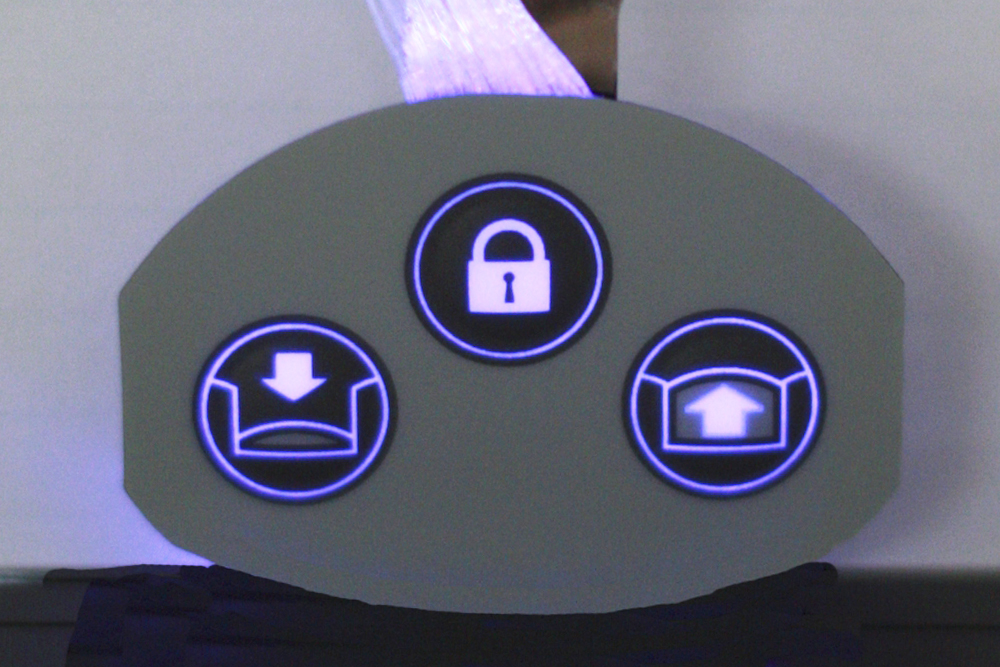

When developing button backlighting, it is crucial to contemplate numerous factors that influence both functionality and visual appeals. The choice of lighting kind, such as LED or fiber optics, considerably impacts exposure and energy performance. Additionally, the illumination degree have to be adjusted to guarantee suitable clarity in different illumination problems without causing glare. The color temperature level likewise plays an essential function; warmer tones can create a welcoming environment, while cooler tones may recommend a more contemporary look.Designers have to also take into consideration the placement and dimension of the backlighting to achieve even distribution and stay clear of hotspots. Moreover, the integration of lowering functions can enhance user experience, permitting personalization based on individual choices. The total style should balance with the tool's style, making sure that backlighting matches instead than detracts from the overall visual appeals. switch backlighting. Each of these considerations is vital for developing a effective and visually enticing button backlighting remedy

Choosing the Right Products for Optimal Performance

Picking the ideal materials is important for guaranteeing ideal performance in switch backlighting remedies. The selection procedure entails thinking about variables such as toughness, light transmission, and thermal properties. For circumstances, making use of top notch polymers can boost light diffusion while keeping structural integrity under differing temperatures. Furthermore, products like acrylic and polycarbonate are prominent because of their excellent optical quality and resistance to yellowing with time.The option of LED components plays a significant role; they should be compatible with the chosen materials to optimize brightness and energy performance. Conductive materials have to be chosen carefully to guarantee reliable electrical links without compromising the total style. Ecological factors to consider, such as recyclability and sustainability, are increasingly influencing product option in contemporary manufacturing. By prioritizing these facets, manufacturers can achieve high-performance switch backlighting services that meet consumer expectations.

The Modern Technology Behind Effective Lighting Solutions

Developments in innovation have greatly changed the landscape of effective lighting services in switch backlighting. The assimilation of LED (Light Emitting Diode) innovation has become an essential advancement, supplying remarkable power efficiency and longevity compared to conventional lights approaches. LEDs eat considerably less power while providing high luminance, making them a suitable choice for backlighting applications.The advancement of clever lighting systems has actually enabled enhanced control over brightness and color temperature level, allowing for greater personalization and boosted user experience. These systems typically use sensing units and programmable user interfaces, adapting to user choices and ecological problems.

Additionally, developments in optical layout, such as reflectors and diffusers, have actually maximized light circulation, making sure uniform lighting throughout various surfaces. This mix of LED technology, smart systems, and ingenious optical elements has actually brought about the production of backlighting solutions that are not just effective yet likewise cosmetically pleasing, enhancing the general capability of devices.

The Production Refine: From Principle to Production

While the journey from idea to production in switch backlighting manufacturing entails numerous meticulous stages, it starts with the design phase, where developers and designers collaborate to establish innovative ideas that meet market needs. This stage highlights functionality and looks, ensuring that the end product is not just reliable but additionally aesthetically attractive.As soon as the style is finalized, models are created making use of innovative production strategies, allowing for real-world screening and improvement. Responses from these tests results in necessary modifications, making certain that the backlighting services execute successfully under numerous conditions.

Complying with effective prototyping, the manufacturing stage commences. This entails scaling up the production procedure, that includes sourcing high-quality materials, applying automated production line, and integrating accuracy innovation to preserve consistency. Each step is carried out with care, ensuring that the why not try this out switch backlighting remedies are prepared for distribution to satisfy consumer assumptions and industry standards.

Guaranteeing Quality Assurance in Backlighting Manufacturing

A robust high quality control system is necessary in the production of switch backlighting remedies to assure that every system fulfills rigorous standards. This system typically includes multiple phases, starting with the selection of state-of-the-art products - switch backlighting. Each element goes through strict testing to validate it lines up with efficiency specificationsThroughout production, drivers carry out real-time inspections to recognize defects early, lessening waste and verifying uniformity. Advanced technologies, such as automated optical inspection, are utilized to keep an eye on soldering high quality and light uniformity, additionally boosting reliability.

Often Asked Inquiries

Just How Do Various Color Styles Affect Switch Backlighting Presence?

Various shades substantially affect button backlighting presence; brighter shades enhance quality and readability, while dimmer tones might cover information. The choice of color impacts customer experience, influencing capability in varied lights atmospheres and applications.What Prevail Applications for Switch Backlighting Solutions?

Typical applications for switch backlighting services include automobile dashboards, computer system keyboards, gaming controllers, appliances, and commercial devices. These options boost usability and visual appeals, providing clear visibility and boosting individual experience in various environments and lights conditions.

Can Switch Backlighting Be Custom-made for Particular Brand Names?

Yes, Switch backlighting can be personalized for details brands (switch backlighting). Makers usually tailor designs, colors, and illumination levels to align with brand identifications, guaranteeing that the backlighting complements the general visual appeals and capability of the itemsWhat Regulations Govern Switch Backlighting Production?

Rules controling button backlighting manufacturing consist of safety requirements, electro-magnetic compatibility needs, and ecological guidelines. Compliance with these guidelines ensures items are risk-free, reliable, and eco-friendly, inevitably advertising customer trust fund and market practicality in the industry.How Do Environmental Elements Influence Backlighting Efficiency?

Ecological factors, such as temperature level and humidity, substantially influence backlighting performance. Extreme problems you can try this out can impact light result, shade precision, and element longevity, eventually impacting the dependability and effectiveness of the brightened buttons in different applications.The production process behind top notch button backlighting options entails several important phases. Choosing the appropriate products is vital for assuring perfect efficiency in button backlighting solutions. Innovations in modern technology have substantially changed the landscape of efficient lighting solutions in button backlighting. A robust high quality control system is necessary in the production of button backlighting services to guarantee that every system fulfills strenuous standards. Common applications for button backlighting options consist of automobile dashboards, computer system keyboards, video gaming controllers, home appliances, and commercial equipment.

Report this wiki page